Your Reliable Furniture Manufacturer

- Providing a quote within 48 hours

- Trusted by 50+ Clients all over the world

- 30+ years of experience in the upholstery furniture industry

Most Popular Products of Rayleigh Furniture

Get what you need even the customized furniture

Who is Rayleigh Furniture?

As a front-runner in the upholstered furniture manufacturing sector, Rayleigh has been successfully delivering top-notch upholstered furniture to both large and small brands for over three decades. Our rich expertise and unwavering commitment to quality assurance have solidified our market position.

Our stable furniture manufacturing process is headquartered in Shanghai, China, where we’ve set up a sophisticated factory and sales office. Here, we’ve established a mature supply chain for upholstered furniture manufacturing and sales, extending our global coverage for furniture distributors. We’re passionate about our business and constantly push the boundaries of our expertise, delivering high-quality, innovative, and eco-friendly product solutions to a wide range of international brands.

Rayleigh Furniture foster strong relationships with leading furniture agents and distributors worldwide, manufacturing and supplying high-quality upholstered beds, sofas, chairs, and more. Upholstered furniture, the centerpiece of any living environment, demands innovation—a challenge that our designers are ready for. They continuously explore new possibilities in style, material, function, and structure, addressing the unique needs of diverse markets.

Why Choose Rayleigh Furniture

Your Best Upholstery Furniture Manufacturer and Supplier in China

Cost-effective Products

Rayleigh Furniture focuses on providing cost-effective upholstered furniture, with detailed cost calculation and control at every stage to maximize product utility and enhance cost-effectiveness.

Certified Quality

Rayleigh holds CE and ISO certifications, demonstrating the company's firm commitment to quality and safety standards.

Innovation

Upholstered furniture, essential to our living spaces, mirrors human ergonomics. Rayleigh Furniture prioritizes its innovative redesign. Constant experimentation with furniture style, raw materials, furniture functions, and structures allows us to cater to diverse market desires for unique products Rayleigh know that only innovation can help our customers gain market recognition

Continuous Innovation

Rayleigh's design team consistently explores new possibilities in furniture design, whether in style, material, function, or structure. They are continuously innovating to meet the demands of various markets.

Rich Experience and Expertise

Rayleigh boasts over 30 years of experience in the upholstered furniture manufacturing industry, offering deep industry knowledge and a wealth of practical experience.

Value-for-money

Rayleigh Furniture specialize in delivering cost-effective upholstered furniture.Our focus spans the entire process—from furniture design, material selection, manufacturing, and quality testing, to packaging and transportation. All steps prioritize high-quality, detailed cost management. Our goal: Improve the utilization rate of product raw materials and shorten the nodes of each circulation link, improve service quality, and provide higher cost performance!

Customer-centric Service:

Rayleigh is committed to bringing clients' furniture concepts to life efficiently and cost-effectively, while staying attuned to market trends and customer needs through regular industry engagement.

Global Supply Chain and Business Network:

With a manufacturing factory and sales office in Shanghai, China, Rayleigh Furniture has established a mature supply chain for upholstered furniture manufacturing and sales.

Services

Rayleigh assure complete design, production, transportation, and post-sales support for our furniture dealers and agents, amplifying their local market competitiveness. We're always ready to assist our furniture dealers, resolving issues promptly and efficiently. Quickly quotations, production tracking, customized furniture, and technical support—these constitute our basic service commitment to our customers!

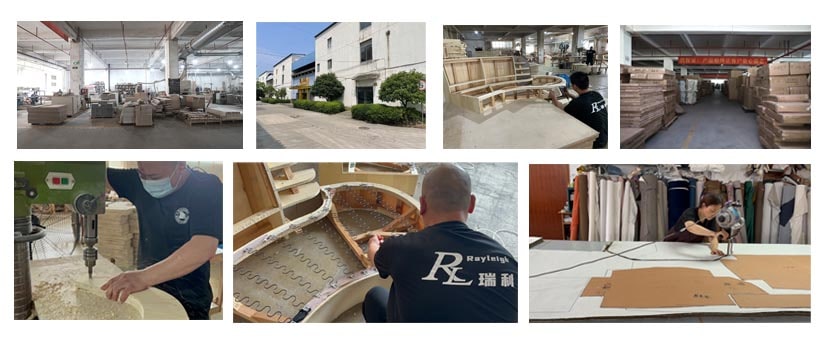

Upholstered Furniture Manufacturing Process

- Raw Material Processing for Frame Construction

Initially, as per the dimension specifications required by the order, the procured raw materials undergo a process of ripping, cutting, and sanding. The cut materials are then assembled into the foundational frame for upholstered furniture. It is crucial to treat the frame for moisture-resistance, corrosion-resistance, and pest-proofing. Depending on the grade of the upholstered item, 0.2-0.4 centimeters thick plywood can be used as a flat base material.

- Fabric Cutting

Upholstered furniture primarily utilizes leather and cloth as fabric. To cater to usage, these fabrics need to undergo preparation and cutting. As per the order’s requirements, the quality of the fabric is first scrutinized, problematic areas in the leather are avoided, followed by a thoughtful layout, and finally cut and shaped manually according to templates, before being sorted and packed. This step is critical to the final appearance and quality of upholstered furniture. If cloth is being used, electric shears can boost efficiency; whereas leather must be hand-cut to ensure quality.

- Sewing and Stitching

Utilizing a flatbed sewing machine, the cut fabric pieces are pieced together. This step significantly influences the appearance and quality of the upholstered furniture.

- Topstitching for Decoration

A single-needle lathe is used to create a topstitch, adding decorative lines to emphasize the shape as per design needs. Then a double-needle lathe is used to further strengthen the stitches, ensuring they are firmly reinforced to prevent cracking.

- Sponge Adhesion

High-density sponge is accurately bonded to the frame’s skeleton, providing elastic support for the upholstery. Precise sponge adhesion is key; otherwise, it can impact the finished product’s appearance.

- Semi-finished Product Inspection

The upholstery and the inner frame are inspected to ensure they conform to the technical specifications.

- Leather Cover Fixation

The cushion’s leather cover is inserted into the seat frame and secured with appropriate nails to achieve a natural look.

- Assembly and Installation

The external frame, kickstand, armrests, and base are installed and test fitted, then adjusted to ensure optimal usability.

- Finished Product Inspection

A comprehensive inspection is carried out on the finished product to ensure that the quality meets the standards.

- Packaging

Once the product is deemed qualified, it is packaged and prepared for shipment or sale.

Accept Customized Furniture

As a professional furniture manufacturer,sofa factory,bed factory, Rayleigh Furniture understand that the era of mainstream, ready-made furniture has given way to modern consumer tastes and trends. With rapidly evolving aesthetics, more customers now opt for customized furniture. Leveraging our expertise, we help our furniture dealers and agents stay abreast of market demands. In line with market trends, we offer timely services in customized furniture design and manufacturing.

What Rayleigh Furniture Manufacturing

Rayleigh Furniture Attended the Exhibitions

Specializing in upholstered furniture, Rayleighis expanding its global footprint. Rayleigh Furniture is dedicated to the research, development, production, and sales of these products. With decades of development, we’ve grown our production capacity, enriched our product portfolio, and established a global presence, becoming a leading upholstered furniture manufacturer. Rayleigh Furniture continuously build bridges of communication with our customers, both new and old. Besides welcoming factory visits from local and international furniture dealers and agents, we also make overseas customer visits. Furthermore, Rayleigh participate in professional furniture exhibitions both at home and abroad every year to showcase our latest products to customers.

What Our Clients Say About Us

Videos of Rayleigh Furniture

Blog and News from Rayleigh Furniture

All You Need to Know About Importing Sofas, Beds and Other Upholstered Furniture From China

The sofa is one of the indispensable pieces of furniture in every family life. However, it is straightforward to buy a couch; you want to

How to Choose the Size of the Sofa?

The sofa is one of the indispensable pieces of furniture in every family life. However, it is straightforward to buy a couch; you want to

How to Choose a Sofa for a Small Living Room?

Small living room space becomes smaller, and the sofa is the largest piece of furniture in the living room. In the choice to pay extra

Advantages and Disadvantages of Solid Wood Sofas

Sofas are a must-have in every home, and solid wood sofas have become an essential part of the modern home. As solid wood sofas can

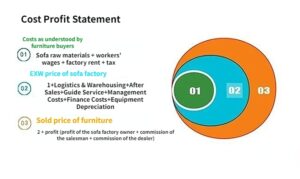

Uncover the Secrets of Sofa Factory Outlets – A Hidden Gem for Furniture wholesalers!

1.The sofa’s cost The relationship between sofa factory price and transaction priceFor furniture wholesalers, the purchase and the understanding of the (cost) ex-factory price needs

The Ultimate Guide to Purchasing at a Sofa Factory

1.The sofa’s cost The relationship between sofa factory price and transaction price For furniture wholesalers, the purchase and the understanding of the (cost) ex-factory price